MickMake Meets Robots and Dinosaurs - Part 2: Robots, projects, electronics and stories

Mick visits one of Tim’s old school mates, Gavin Smith, who runs a MakerSpace called Robots & Dinosaurs in Meadowbank, Sydney, Australia. Part 2 looks at Maker projects, 3D printing, electronics and yet more stories.

Part 2: Robots, projects, electronics and stories

Check out Part 1 of this transcript and video.

(Transcript)

Lost In [a Maker] Space

What is this?

I'll show you.

Ready?

Yeah.

The big unveiling.

OK, let me guess.

Nice.

Oh my goodness.

So this is B9 from Lost in Space. One of our members, John, has been working on it for several years.

Camera

Oh my.

Nice.

It's all scratch built. I think they used a fiberglass mold for this bit, but the rest of it's all hand done and soldered together and carefully polished, and, yeah. It's a labor of love.

Even the retro light thingies, man.

So.

I've seen endless discussions about what the original lights were, and the colors and the like.

And there wouldn't be any plans for it so you have to actually have to watch the movie over and over and over. Sorry watch the TV series over and over and over.

There's actually a community of people that make B9 robots and other ones.

Right, right.

Yeah, it's a very, very cool suit.

Camera

Toaster to robot

Is that an old toaster?

Yes. And a printer and ...

A printer, yeah.

Ah, yeah. It's recycled.

A printer, what a great way to use a printer.

I was just telling Mick before that his old, big old laser should be used as a beer fridge.

Nice.

It's big enough, I reckon.

Plus you could have it in your office and no one would be the wiser.

One of the guys does some consulting work with the university and he's making them a robot that actually lifts up or goes and finds cans and lifts them up and puts them in places and stuff so I'm guessing that's what all the background to all these is for...

Camera

Book scanning

Book scanner.

I thought you said scanner, I was like, okay. Bar codes.

So you throw the book in there. There is a pair of cameras on the side. There's a touch screen to operate it, down flip up, click, down, flip up, click.

I like how it's counter-weighted.

It's quite easy to use, I've done like 1200 pages.

And you hit the button?

In a couple of hours.

Will this be the button?

That will be the button at some point.

On the handle.

The cool thing about this is, somebody made a Raspberry Pi distribution which is read-only. So what happens is you power it on, you stick a USB stick in there to put all your stuff on it. It saves to that. When you're finished, you just turn it off and you don't have to worry about it getting corrupted or configuration files or anything, it just does it. Anything else that requires updates or requires configuration would eventually get broken and then it would just sit unused.

Camera

Dancing foliage

The prototype which is hung which works much better is a third prototype and then the fourth one is gonna be in this box here.

What was that Kickstarter called?

Slow dance, I think? And then they did the Kickstarter.

There's a bit of dancing, bit there, okay? Let's see what happens to that.

I can still see it.

You'll probably get a much better thing if you go grab another flower from the garden and then play around with it.

It's not moving as much but you can see that it's sort of deforming at the top.

Camera

3D printing

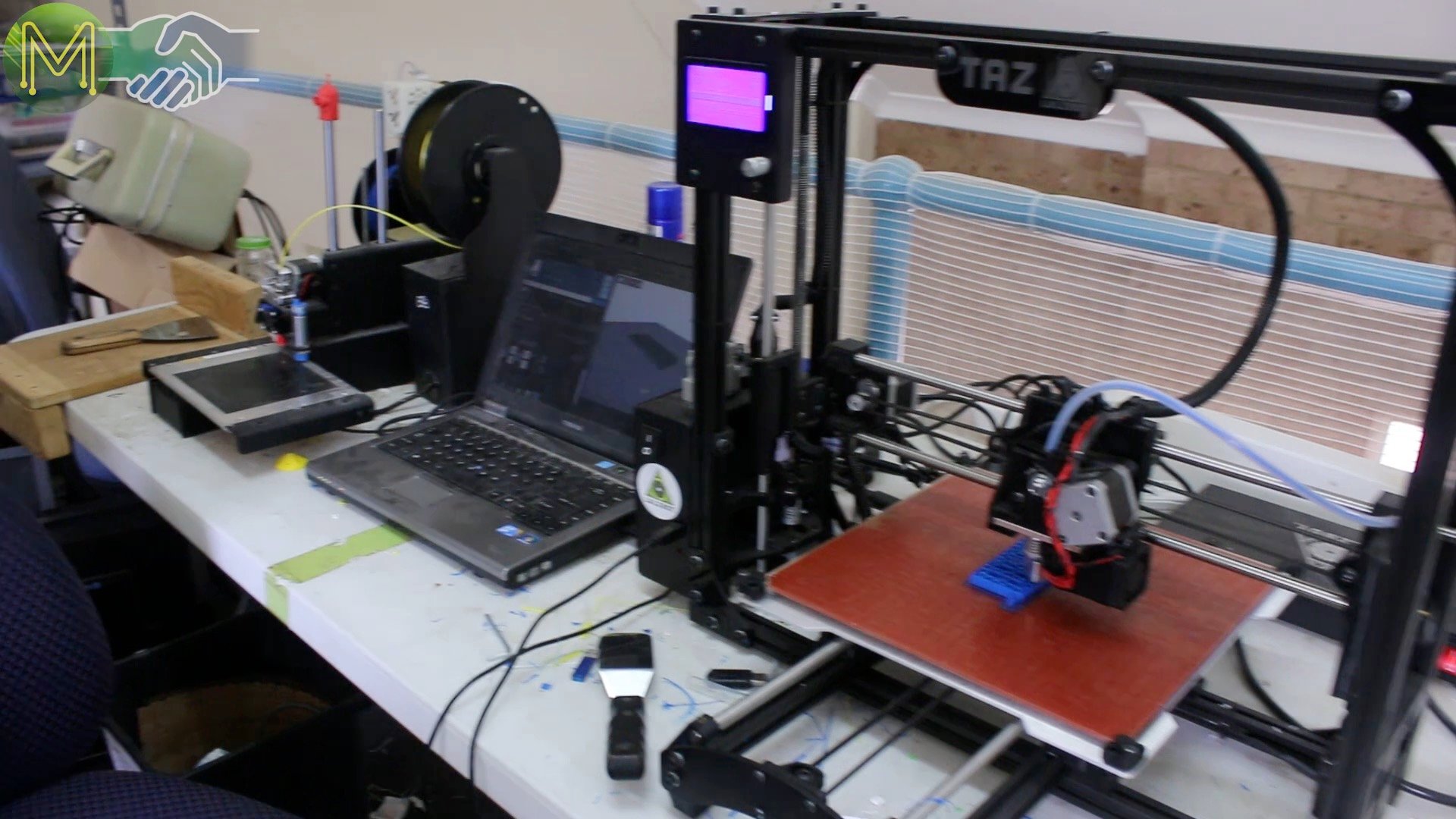

So, upstairs, eh?

So this is upstairs, a bit messy at the moment.

This is pretty tidy. Is this another, what is this? Oh, it's a 3D printer.

3D printer. 3D printer, 3D printer, 3D printer.

A lot of people have printers, and they say 'oh sorry it's actually stopped this week 'cause I've got to repair it.'

Especially in the communal environment, you occasionally you have people that don't know what they're doing break it or you have people that think they know what they're doing try and help and yeah.

Camera

That's gonna be a door for Minecraft. I've got a doorway that I've cut on the laser cutter downstairs, using the box generator to make a doorway, and that will go in it and then I've got a stepper motor that'll sit undernearth it and make it open and close.

Cool.

And there's a fan, so that'll be PLA?

It is PLA. So it's. The temperature is there as well. So the head is at 200 degrees. And the bed is sitting on 50 degrees.

I used something called OpenSCAD, which is a programming language. You define 3D primitives like cubes and spheres and cylinders in code and it lets you combine them and slice them in different ways. So this is built up from a bunch of rectangles and cubes and some cylinders that I've just combined. The slicer is responsible for turning it into layers and also calculating all that info.

Camera

Gavin’s storage solution

This is where I'm most comfortable. I saw the soldering iron and the wires I thought, 'Okay, I'm home now.'

We've got a bunch of tools for doing surface mount stuff, for doing all sorts of electronics, and a bunch of bits and pieces for people to borrow and use for their own projects and we've got a very large parts collection which I'm very proud of this organizing.

Camera

Look at all this labeling. Oh my goodness, this is very, very new person friendly.

Yeah that's exactly what I was aiming for, is if you're not familiar with electronics, you can still figure out where stuff goes.

This is really cool, yeah.

And the cool thing about pictures is, every time you go in and grab something, just subconsciously the pictures, it's like you're moving through a forest and you're remembering the layout of everything. So you don't have to read the stuff, it's just you're coming up with this map in your head without even trying.

I have about 10 of these things at home. 10 freestanding filing cabinets worth of stuff. Because with the amount of parts that I have, I would not survive.

So this is inspired after seeing Adam Savage's, Adam from Mythbusters, had a big thing on his tool organization system. And that's great but it's incredibly expensive. And they're thousands and thousands of dollars for the racks. And I went, 'Well, I could just make it...'

Let's just put plywood, and some brackets.

But the key to this was this stuff here, it's called Datastrip. And it's actually what they use to hold price tags on shelves. So I ordered Datastrip on Ebay and just screwed it on the front right there. And then I can just take a label and throw it in the front. And that's really handy for me, because if I change the purpose of the box I can just pull out the label real quick, scribble something with a pen, and then throw it back in there.

I ended up driving around to Port Kembla or something and finding some office supply store and buying a bulk order of like 50 meters of Datastrip and loading it in my car, and then yeah.

Okay so obviously you've used three meters, so he's got 47 meters to go.

I like it when something's so good you go, 'You know what, I'm almost out of space but I'm gonna get one of my own.'

Camera

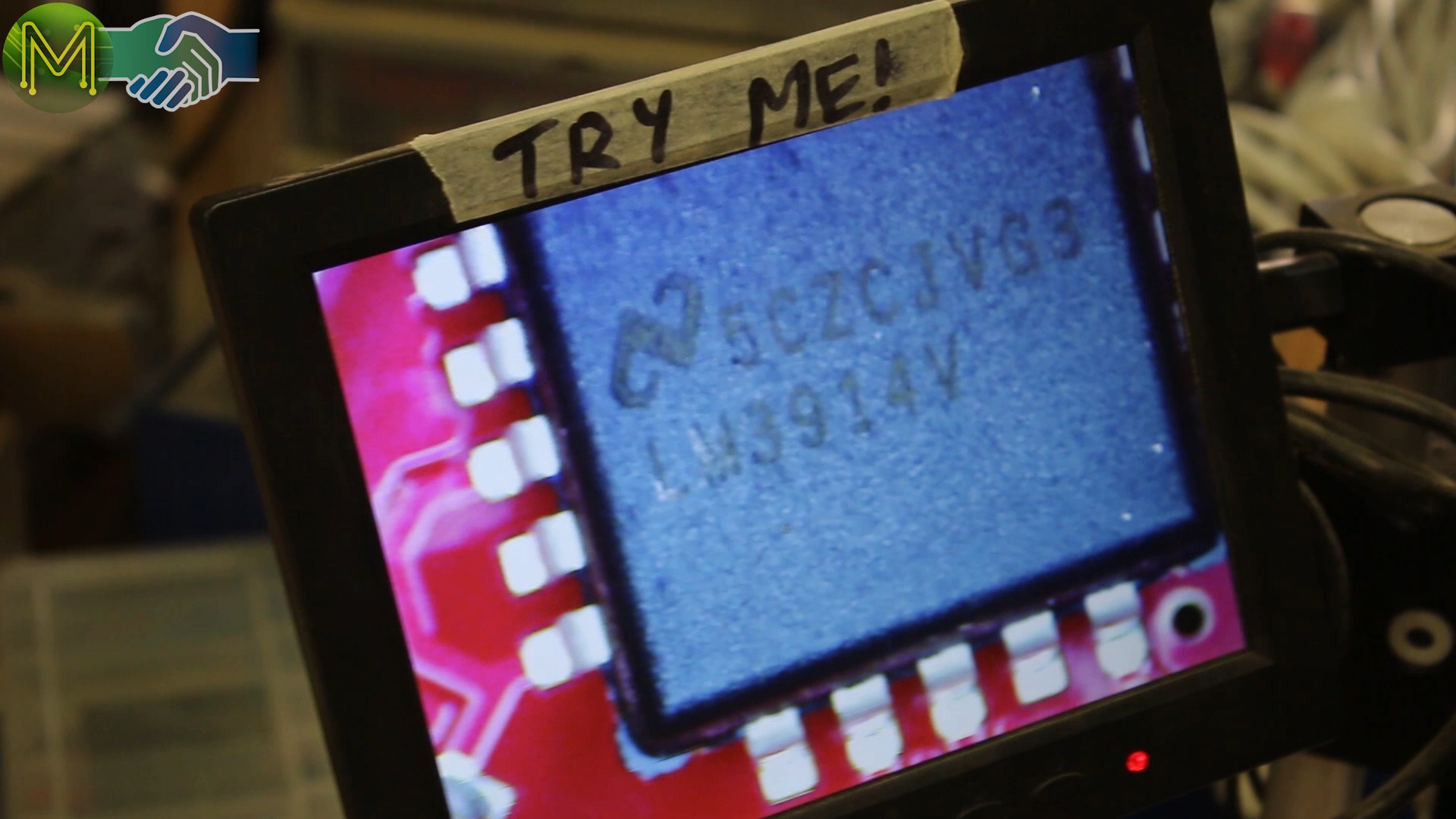

The macro world

So that's actually self contained is it?

Find a little target we can put in there. There you go.

Yeah excellent.

Oh I've seen YouTube videos of this called 'Look at this chip,' and they use this method to help you identify the -

The size of the.

Everyone knows it's three and a half mms. Wow that's so good.

Yeah. You can get some insane detail with that. It's very handy for surface soldering.

Oh yeah.

Camera

Melting plastic

If you want, we'll get the kettle out. The Kickstarter for that was virtually a case of; carry that in your wallet as a business card. And then if he needed to, a quick and nasty fix all you need is a kettle. So I carry a couple of those around just in case. Alright so it'll be way too hot actually.

It melts at 60 degrees. I'll just let it melt and put some cool water in there.

It's already going clear now.

I should have just used hot tap water but it's cool stuff. I don't know if it's a melting thing or a glass transition temperature so it may not actually lock the phasing like melting ice does. I wouldn't rely on it preserving the temperature change.

Let's make something with that. And then what I'm gonna do, is drill a hole in it and then tap the hole so that it accepts a screw, and then we'll see if it actually holds that hole.

Is that a housing.

So as long as you don't get any moisture in there.

Eh.

Yeah, well.

Camera

Xray machines and flash drives

A few years ago I was in Japan for a work thing. We were commissioning an x-ray gauge for a steel mill. And when you're rolling steel there's two huge rollers and the steel goes through and you -

To flatten it out?

To flatten it out, yeah. But to figure out how much pressure you should apply, you need to know what the thickness coming out is. So you need to measure this red hot steel and figure out how thick it is. A few ways you can do that is, using an incredibly intense beam of X-rays, shooting it through the steel, and seeing how much gets through to the other side. And this is intense enough that they can measure the thickness down to microns with a really fast response time.

We're doing a little commissioning and there was a little bit of a lull while we're waiting for stuff to happen. And I'm like, 'We've got a big x-ray source here, doesn't happen very often.' So we loaded up a bunch of USB sticks and SD cards with files and I did like an MD5 and checksum, verify the data every way that I could. Stick it on the USB stick. Go shut the beam down and then carefully put a piece of paper with the USB sticks in the middle, and go turn it back on. And I'm giving it five minutes, go measure in the computer, give it ten minutes, go measure. I could not flip a single bit.

The Japanese engineers figured out what I was doing and they started getting curious. And they go into the control panel and shut it down, and they put in a special code that removed all the attenuating filters from the thing. So they had a much more intense beam. They crank up the kilovolts so it's like this incredibly intense beam. And we gave it like ten minutes on the highest settings we could. Couldn't flip a single bit.

Was everyone wearing lead suits?

No, we had those cylinders and we had all the radiation safety taken care of. So this was about 2005 with SD cards I bought on the shelf around about then. So maybe they've gotten smaller and maybe now they're vulnerable to radiation but as of that time I can definitely say I really tried hard and we really couldn't flip a single bit. So yeah.

Camera

Tapping plastic

So I reckon that we should try and give that a drill and a tap.

Oh yeah?

You can feel it in the thread.

This is a really neat trick that people should be aware of, if they ever need to move something really precisely. When we were drilling the hole we looked up an M3. So an M3 has a .5 pitch. So half a millimeter between adjacent threads on the screw. And then 4 has .7. So you can use a technique called a differential screw, where you put the two back to back.

So this is an M3 here?

Yeah.

And an M4?

So .5 mil pitch and a .7 mil pitch. And if I turn it that way, one thread goes off that one, and one thread goes on that one. So it goes .7 this way and .5 that way. So it's moved 200 microns with one turn.

You can easily do a half a turn or a quarter turn or maybe an eighth of a turn. So you can easily precisely move something by 20 microns or by 15 microns or something like that. And this is actually how the really precise micrometers work, is there's a differential screw inside it.

Camera

More tools

Something I'm reasonably proud of. This is all common tools in a space just ready to go. We've got your Vernia Calipers there, we've got your hex keys, all the spanners, individually labeled, so they go back in the right spot. 'Cause if they're not labeled, they won't go. If it's not easy, then people won't do it. You've got your saws, you've got your other bits and pieces. Otherwise it would just end up with a big pile of crap in front of it.

Yeah so like my garage, pretty much.

Yeah, that's it. Another thing I'm pretty proud of is this thing here, it's a screw and bolt sizer. Both metric and two different versions of imperial stuff.

Only imperials can count with two different versions of themselves.

That's it. So if you've got a bolt and you need to get another one to match it and you're not quite sure what it is, you just come along and screw it in there and see what happens.

M3 screw, that's the famous Nerf battery door screw size.

I can tell there's hours of angst in there behind that statement. I'm guessing it was not a simple journey to find that.

Yeah.

Camera

Check out Part 1 of this transcript and video.